Week 6 Laser Cutting, Introduction to the Electronics

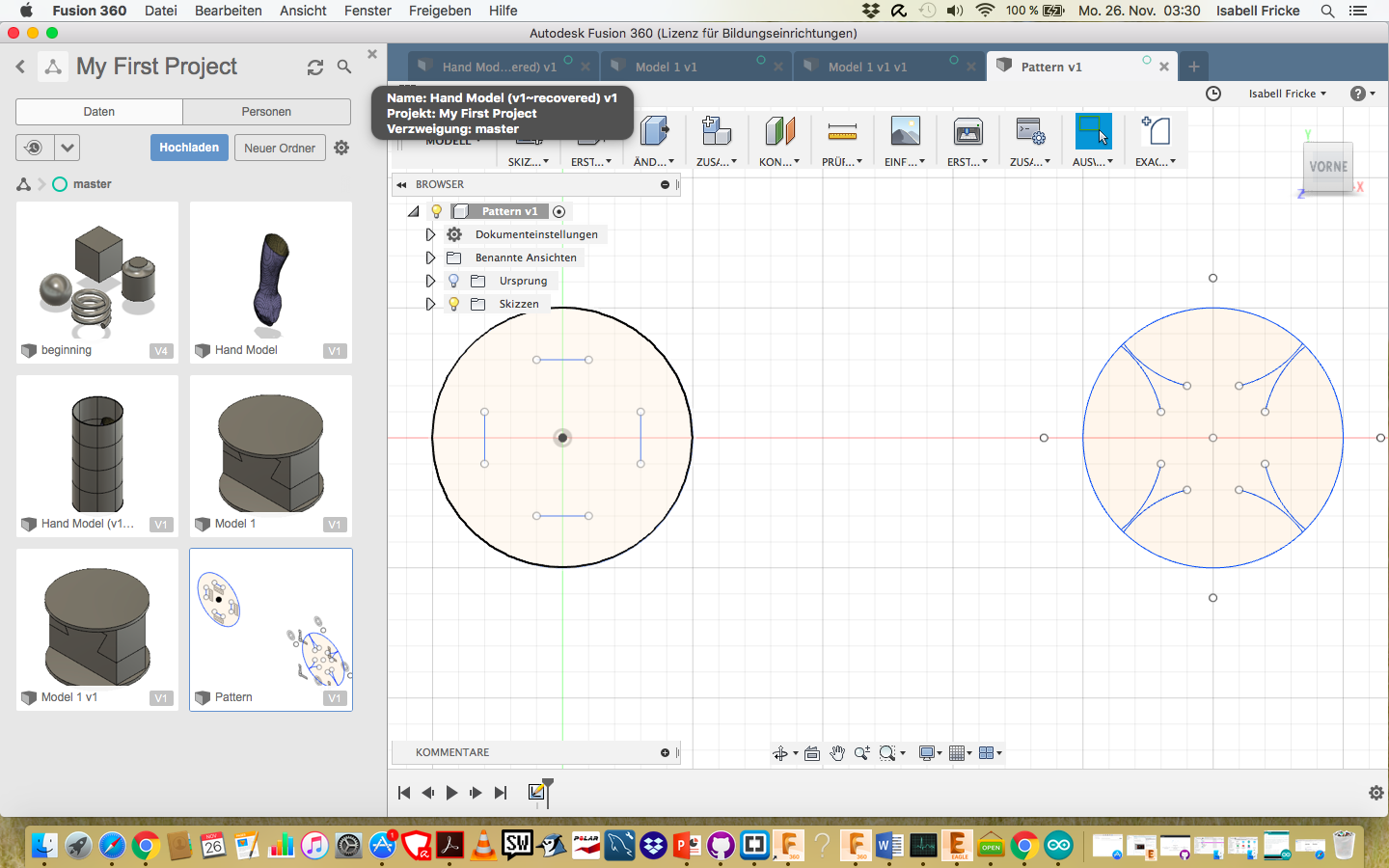

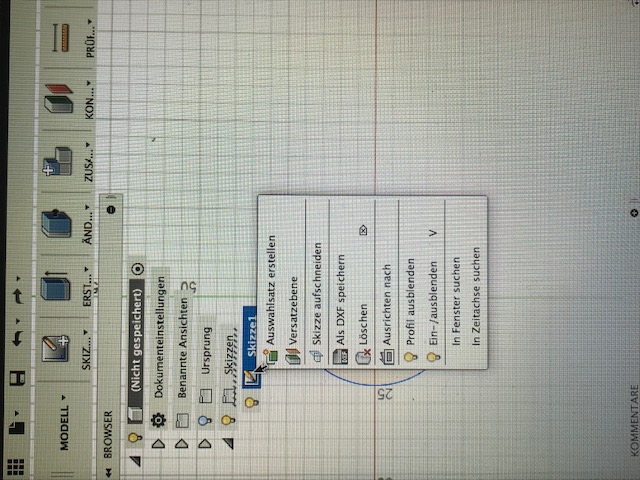

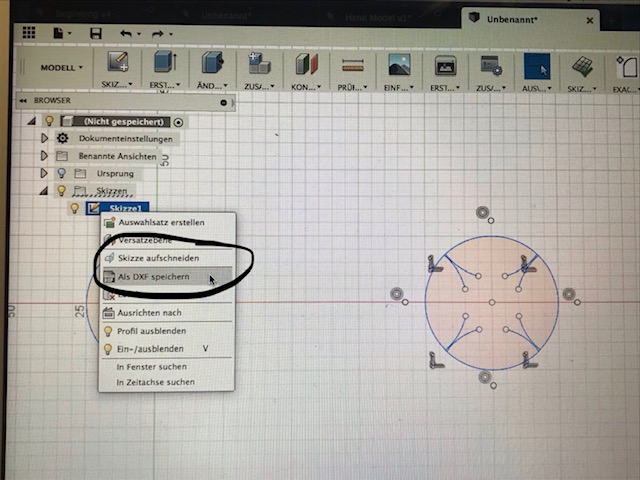

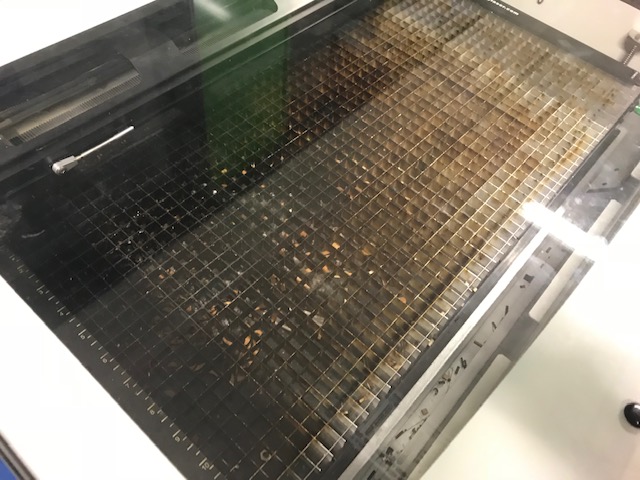

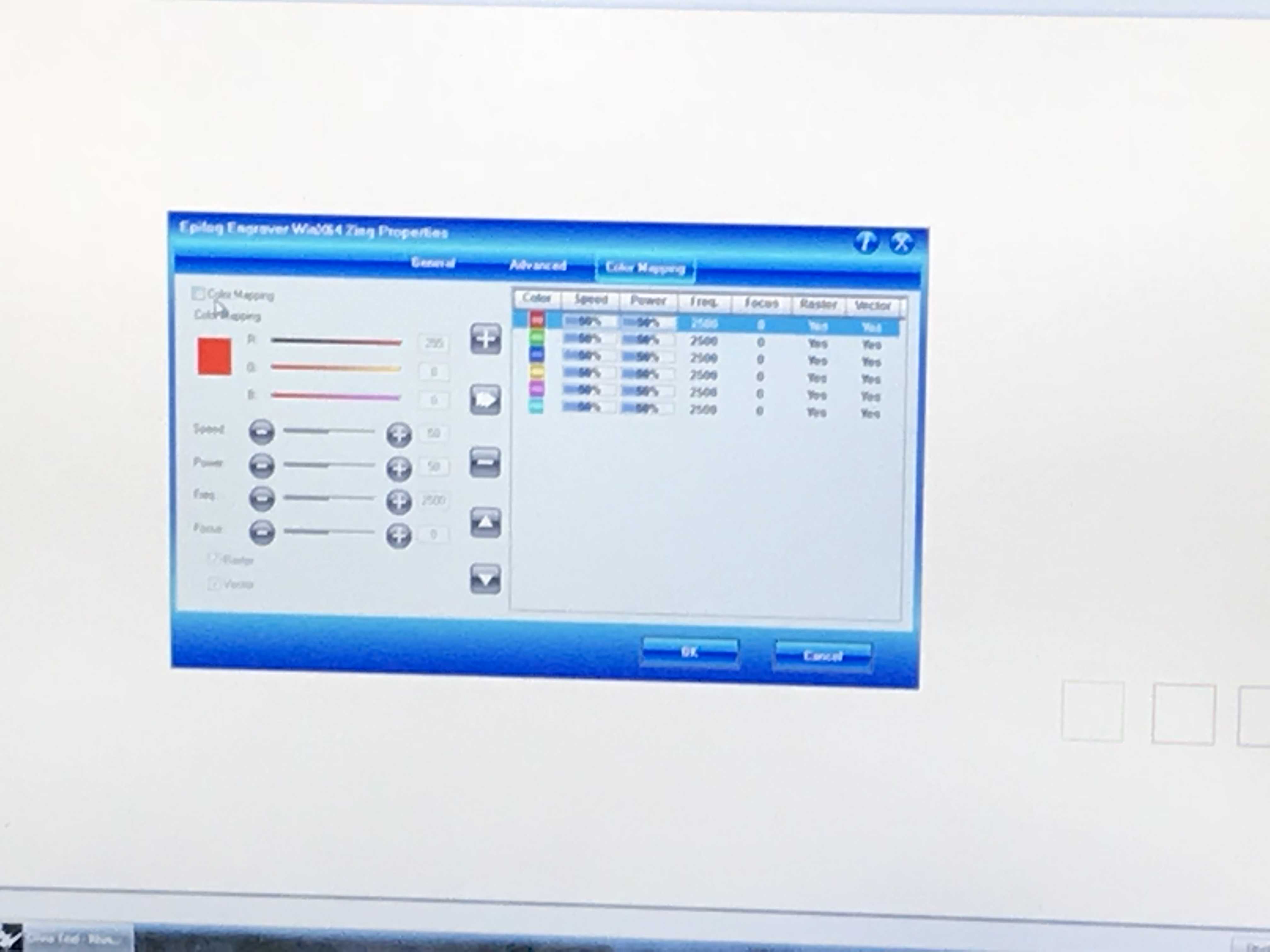

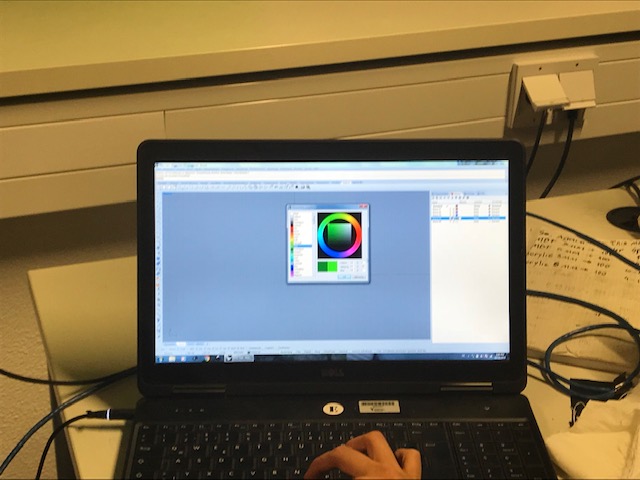

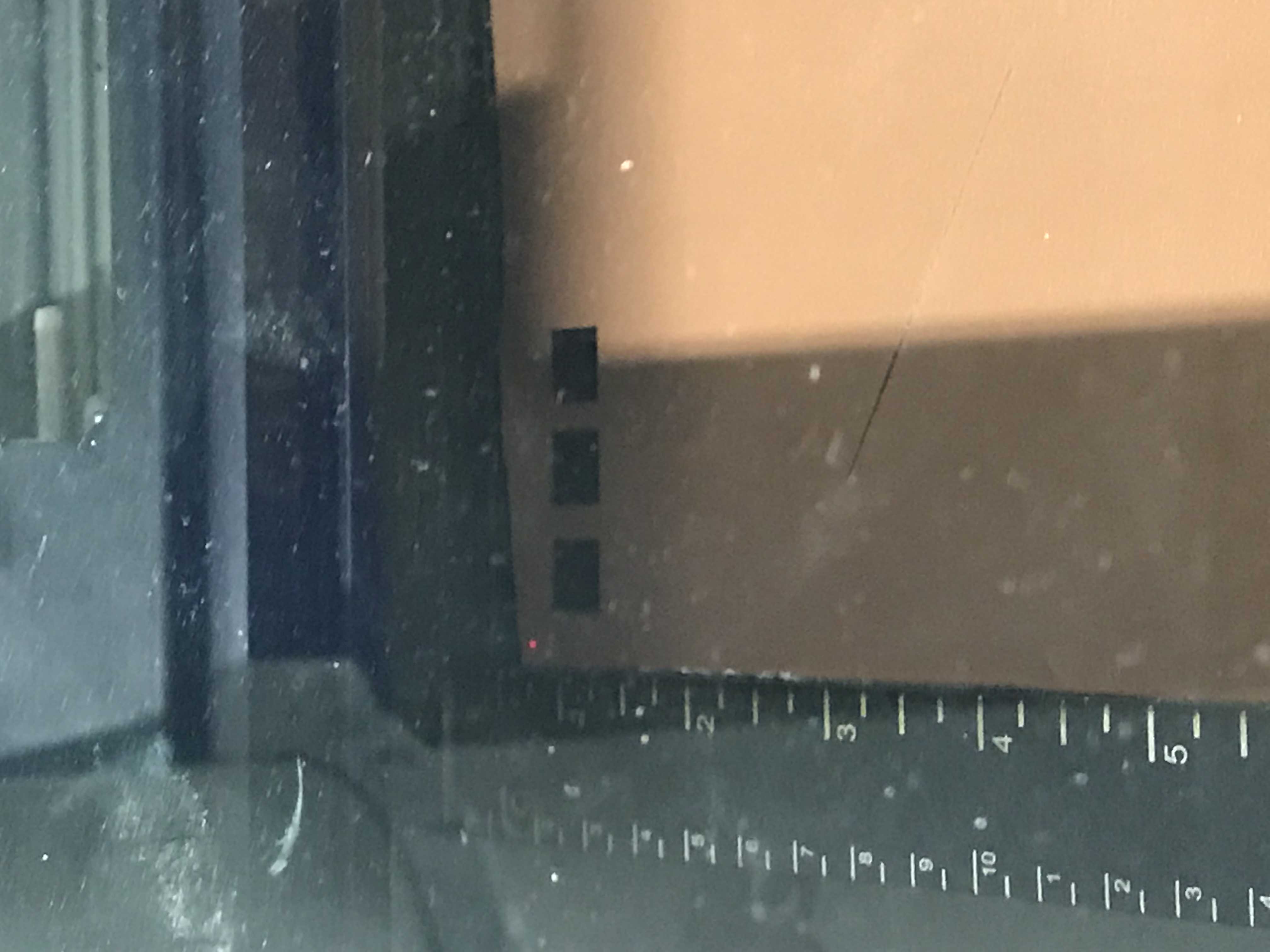

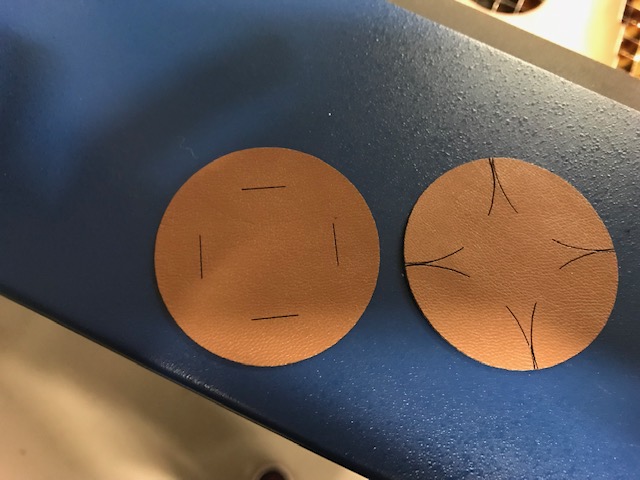

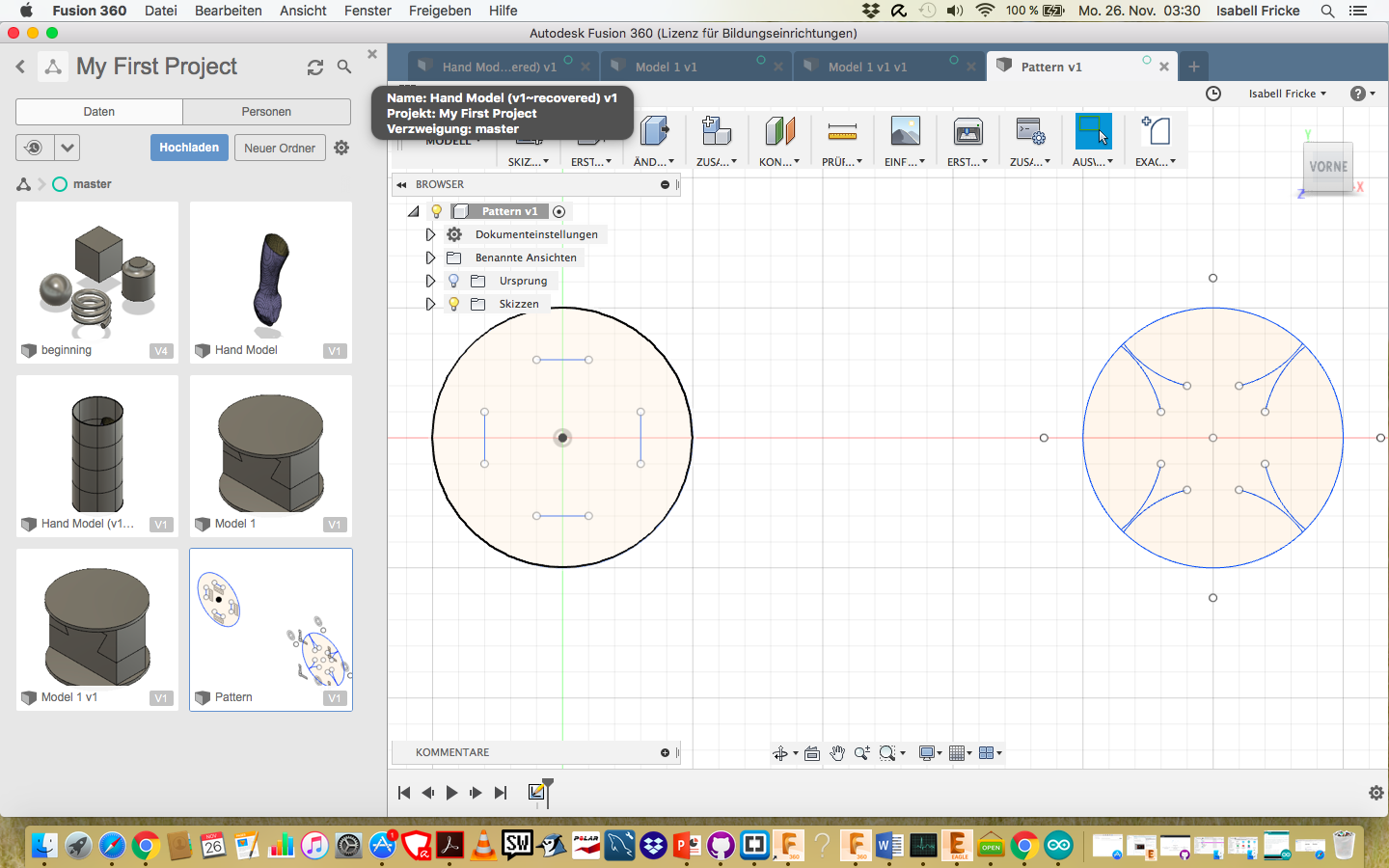

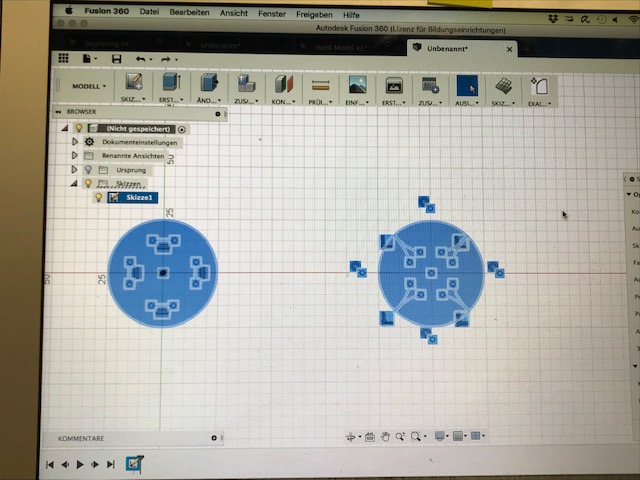

In the sixth week of the Interdisciplinary Project Fabrication for Care, we continued to work on our 3D models. The hand model can be used for different purposes. On the one hand you can create an orthopedic splint out of it, on the other hand you could also use it as a form for an artificial hand (arm) where in the end the electronics are installed. After being briefed by Adriana on the different usage methods, we created our samples (with fabrics or leathers) with Fusion 360 and cut them out on the laser cutter. First, we create our pattern in Fusion 360 °. This is relatively easy in Fusion simply select a circle and drag it to the desired size. Then use the tools lines (curved / straight) to edit the places that the laser cutter should later cut.